12

يونيو8 Experimental And Mind-Bending Tamagoyaki Pan Test Techniques That You won't See In Textbooks

England wicketkeeper Ben Foakes will return to the facet for the primary Test in opposition to India in Hyderabad, captain Ben Stokes has confirmed. Step 7: Postprocessing - Many 3-D printers would require some amount of publish-processing for the printed object. Binder 3-D printers make two passes to form every layer. SLS depends on a laser to melt a flame-retardant plastic powder, which then solidifies to form the printed layer. Selective laser sintering (SLS) is one form of sintering utilized in 3-D printing. SLA makes use of photopolymerization, directing a laser throughout a vat of liquid plastic known as photopolymer. As with inkjet 3-D printing, the SLA repeats this course of layer by layer till the print is completed. Some of PT CAM's training included a stereolithography apparatus (SLA) by 3D Systems. In the 2000s, the Piedmont Triad Center for Superior Manufacturing (PTCAM) was a partnership of colleges and businesses that supplied fingers-on coaching in metalworking abilities in North Carolina. Look over the coaching instruments provided and have a look at to find one that provides visual aids in studying this system. When you figure that a programmer prices one thing like $150,000 per year (once you embrace all the things like the programmer's wage, benefits, office house, tools, management, coaching, and so forth.), you'll be able to see that it may well price a company tens of millions of dollars to fix all of the date calculations in a large program.

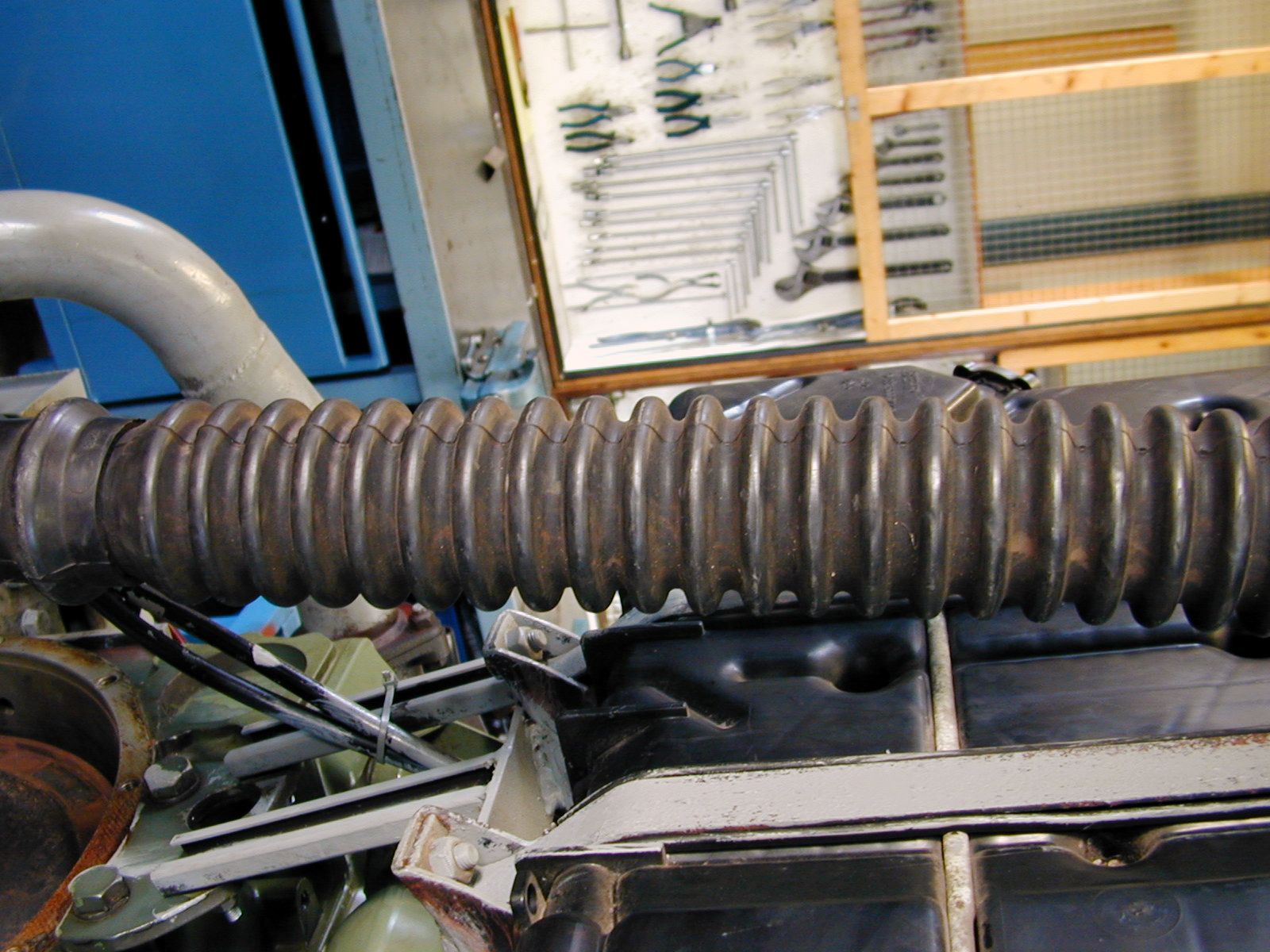

In CNC machining, materials is faraway from some pre-current block until the completed product stays, very like a carving a statue from stone. Most newborns just like the feeling of being securely wrapped in a blanket. Marriage ceremony kind to perform in window remedies can present a fun problem when you have an odd-formed window. Not like 2-D printing, though, the nozzles or the printing surface transfer up and down so a number of layers of fabric can cowl the identical floor. For instance, the automotive business has used 3-D printing expertise for many years for fast prototyping of latest auto half designs. Kurt Tank had a hand in numerous designs that proliferated at Focke Wulf throughout the battle, together with the less-than-successful reply to Britain's de Havilland Mosquito, the Focke Wulf Fw Ta-154. Analysis company EADS has an excellent bolder ambition for 3-D printing: to manufacture aircraft components themselves, including an entire wing for a big airplane. One other benefit is which you can incorporate a wider variety of colours and materials in the method, including metals and ceramics. MIT licenses corporations to develop products that use 3DP, but to qualify, the corporate should use some unique mixture of powder and binder supplies.

Binder 3-D printing has a couple of advantages over direct 3-D printing. Subsequent, let's study the final means of printing three-dimensional objects, which applies no matter what method you are utilizing. Step 1: CAD - Produce a 3-D model using laptop-aided design (CAD) software. The constructing platform then lowers barely to accommodate a new layer of powder, and the complete process repeats till the mannequin is finished. Sintering is of course compatible with building steel objects because steel manufacturing often requires some kind of melting and reshaping. To actually taste it the Italian means, order the Pizza Margherita sort. Moreover, these printers don't use ink; they dispense thick waxes and plastic polymers, which solidify to type each new cross-part of the sturdy 3-D object. Unlike direct printing, though, binder printing uses two separate materials that come together to type every printed layer: a tremendous dry powder plus a liquid glue, or binder. The primary cross rolls out a thin coating of the powder, and the second go makes use of the nozzles to use the binder. MIT's 3DP course of, mentioned earlier, uses this binder approach. Fused Deposition Modeling (FDM) is an additive manufacturing approach that's related, although not identical, to direct 3-D printing.

To this point, we've checked out how 3-D printing has developed and four widely adopted 3-D printing technologies. EADS researchers see this as a green technology, believing 3-D printed wings will reduce an airplane's weight and, thus, cut back its fuel usage. The software program program might provide some trace as to the structural integrity you probably can expect in the completed product, too, utilizing scientific data about sure supplies to create digital simulations of how the object will behave under sure situations. Their peak depends on the species, they usually bloom from May to September in a mess of colours. This 3-piece set options a 3-inch, 5-inch, and 7-inch diameter pan, all with a top of two inches. FDM can create objects with features as small as a fraction of a millimeter. Step 6: Removal - Take away the printed object (or a number of objects in some instances) from the machine. The brand new print may be weak during this step since some materials require time to cure, so warning is perhaps mandatory to make sure that it would not break or fall apart. The term "atomic clock" may conjure up scary, 1950s-horror movie mental photographs: A Doomsday gadget, constructed by a lab coat-wearing maniac in a mountain fortress, is ticking away the seconds before it wipes out our entire planet.